For the second time, jumavis® is presenting itself on the big international stage. From October 8 to 10, 2024, the young company will be showcasing innovations and trends in current and future technologies in image processing for optical quality control at VISION 2024 in Stuttgart.

Managing Director Johanna Unrath and her team will be focusing on „live demos“ of highly interesting innovations such as a high-resolution microscope camera with measuring software from DeltaPix in combination with a telecentric lens from Vico. A system that enables highly accurate measurements with unprecedented precision. Also presented is a 20 mega pixel camera from Basler with viewer software, which in combination with the motorized Navitar lens allows extreme flexibility in working distance and field of view. As a further attraction, jumavis® will be showing a 3D sensor from LMI Technologies – a world leader in 3D scanning and inspection: „Gocator 3D sensors“ are ideally suited for use in robot-guided quality control.

The fourth live demo is dedicated to difficult lighting situations. As the exclusive European distributor of the lighting specialist „Spectrum Illumination“, jumavis® will be presenting solutions for extreme requirements with high-performance LED lighting – for use with particularly large objects and distances. For smaller lighting situations, jumavis® will be presenting smart and intelligent lighting solutions from its large pool of competent partners.

jumavis® will also be presenting innovations from all its partners in clearly laid out showcases, proving once again:

that jumavis® is THE specialist and distributor for all applications in optical quality control. Consulting, compilation and feasibility studies – all from a single source.

Would you like to visit us at VISION 2024 in Stuttgart? Then please do not hesitate to get in touch with us. We will be happy to schedule an appointment for you.

You can obtain your personal admission ticket here.

The reliability of optical quality control stands and falls depended on the quality of the „eye“ – it determines whether what is important is also seen.

With the Navitar® ZOOM 7000-2, jumavis® partner Navitar® introduces a macro lens that enters new spheres of quality. For over 45 years, Navitar® has been a leading manufacturer of standard and customized optics, optomechanical subassemblies and optoelectronic technologies and systems and has built up a good reputation in optical quality control over these years.

Launched in 2008, the Navitar® Zoom 7000 has now undergone a comprehensive redesign to further enhance the imaging quality of this legendary and reliable lens with a focal length range of 18 – 111 mm. The Navitar® ZOOM 7000-2, the next generation of the macro lens, has been redesigned, refined and optimized for demanding applications in machine vision, life science and research following optimized and more precise manufacturing capabilities.

With its exceptional optical performance, this versatile, close-focusing lens delivers outstanding image quality across a range of magnification ranges. Its robust construction ensures reliability even in demanding environments while offering excellent value for money and flexibility.

● 18 – 111 mm focal length with manual zoom

● Working distance 5” to infinity

● Parfocal across entire zoom range

● Image capture of objects larger than 1” ø

● Compatible with sensors 2/3” or smaller

● Dimensions: 67 x 178,2 mm

● Mount: C-Mount

● Weight: 840 grams

Would you like to know more about the Navitar® ZOOM 7000-2 and its wide range of applications? Then please do not hesitate to get in touch with us.

A few weeks ago, jumavis® ventured onto the big international stage for the first time. From April 23 to 26, 2024, the young company presented itself at the „36th Control“, the international trade fair for quality assurance in Stuttgart.

„It was a great challenge for us and our stage fright was enormous,“ says Johanna Unrath, Managing Director of the specialist for optical quality control, founded in 2022, „but just a few hours after the opening of the “Control 2024”, the nervousness gave way to great joy. The interest shown by many trade fair visitors in us, our services and products was overwhelming“.

The jumavis® team made every effort to offer trade fair visitors something interesting. Even from a distance, „movement“ was visible on the stand. A cobot installation with „Gocator 3D sensors“ from LMI Technologies demonstrated the future of fully automated optical quality control. Combined with AI-based software, systems of this kind can revolutionize the monitoring of product quality and help manufacturers advance into completely new quality dimensions.

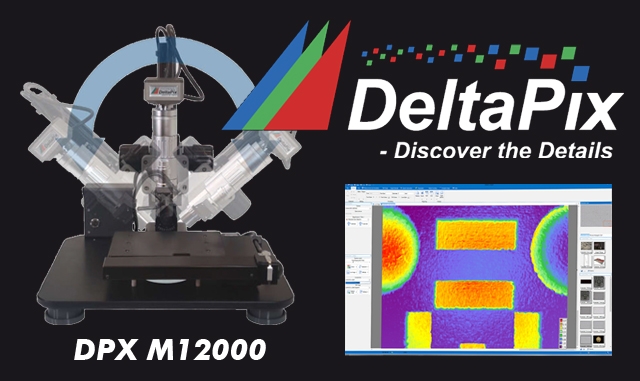

The second „highlight“ was provided by jumavis® partner „DeltaPix“. At three workstations the team around CEO Steen Oersted presented hers latest developments – including the revolutionary DPX M12000 – a high-precision, fully automated digital microscope that offers image quality and functions such as 3D topography, high depth of field, auto-stitching, automatic scanning and much more, which is a novelty in this price range. DeltaPix also presented two extremely economical systems with a range of functions adjusted to the respective requirements.

A trade fair is not just about presenting new products and services, it is also a social event. The opportunity to look each other in the eye and experience the sensor or software at work under (almost) real conditions has a completely different quality to an online meeting or a phone call. Over the four days of the trade fair in Stuttgart, many visitors were able to gain an impression of jumavis®’s expertise, performance and extensive range of products.

„We were particularly pleased with the great interest shown by visitors who were previously unfamiliar with jumavis®,“ says Johanna Unrath, „but we also saw many familiar faces.“ „All in all, we see it as the right decision to exhibit at “Control 2024” and are already looking forward to the next opportunity, the “Vision 2024”, which will take place in Stuttgart from October 8 to 10, 2024.“

„My heartfelt thanks go to our team, which was already very committed in the run-up to the trade fair, provided perfect consulting service during the trade fair and is now also handling the many contacts and inquiries after the trade fair with great care.“

Would you like to know more about jumavis® and our extensive range of products?

Then please do not hesitate to get in touch with us.

Just two years after its founding, jumavis® is venturing onto the big international stage for the first time. From April 23 to 26, 2024, the young company will be exhibiting at the 36th Control in Stuttgart, the leading international trade fair for industrial quality assurance.

„We are very proud of how positively our company has developed since it was founded in March 2022,“ says founder and Managing Director Johanna Unrath. „Even in the first year of our existence, many customers placed their trust in us. Our partners and suppliers, who I had already cooperated during my time at Polytec, also remained loyal to us. This enabled us to demonstrate our expertise in all areas of optical quality control right from the start we were prepared to deliver immediately as a specialist in image processing components.

As a result, jumavis® was able to advise its customers well right from the start and convince them with continuity and reliability, achieving a positive result in its very first year of business. Since then, jumavis®’s turnover has grown continuously and the team has expanded steadily.

„We want to continue on this path and will demonstrate our capabilities at the 36th Control trade fair in order to find new customers as well as innovative partners and suppliers,“ says Johanna Unrath. „Optical quality control is a very dynamic and fast-growing area in modern industrial companies. Technical progress is rapid and we at jumavis® are doing everything we can, to stay at the forefront.“

As a special „highlight“, jumavis® partner „DeltaPix“ will be presenting its newest product for the first time in Germany – the DPX M12000 – a high-precision, fully automatic digital microscope that offers image quality and functions never before seen in this price class. The DPX M12000 enables 3D topography, high depth of field, auto-stitching, automatic scanning and much more. A team from DeltaPix, led by CEO Steen Oersted, will be personally present at the jumavis® booth to demonstrate the outstanding performance of the DPX M12000 to interested parties. In addition to the DPX M12000, „DeltaPix“ will also be presenting exceptionally economical systems for a range of functions adapted to the application at Control 2024.

As a further attraction, jumavis® will be presenting 3D sensors from LMI Technologies – a leading global provider of 3D scanning and inspection: „Gocator 3D sensors“ are ideally suited for use in robot-guided quality control.

Would you like to visit us at the 36th Control in Stuttgart? Then please do not hesitate to get in touch with us. We will be happy to schedule an appointment for you.

You can obtain your personal admission ticket here. [External link for registration]

jumavis® sees itself as a system supplier and offers its customers comprehensive solutions, even for difficult tasks. Every optical quality control system needs a reliable and functional mounting system. It must be possible to integrate the precise system components easily, well protected and reliably positioned into a stable overall system.

Everyone knows the problem: space must often be created for the optical quality control system, which is equipped with sensitive components, in cramped and unfavorable conditions in the production plant, in which the optimal illumination, the ideal camera angle and reliable passage of the test parts are possible.

The specialists of jumavis® know the right solutions here and, together with our partner autoVimation, which has won the “Karlsruhe TechnologyFactory Innovation Award” several times, we offer mounting systems, protective housings and a wide range of accessories which allows to use image processing systems almost under any environmental conditions. This extends to extreme temperature ranges, for which camera housings with water cooling systems or Peltier air conditioning are required. Our solutions are as versatile as the tasks involved.

In the pharmaceutical and food industries we have very special requirements. Absolute hygiene and maximum chemical resistance are required there. With the autoVimation Hygienic Machine Vision-Building Kit, jumavis® offers its customers a freely configurable V4A mounting system with hygienic all-round protection for complete systems with seals between all metallic parts and IP69K protection of the entire system by routing the cables within the mounting components.

This provides our customers a certified solution that meets all national and international standards and even saves time and money thanks to the intelligent use of prefabricated parts from the sophisticated autoVimation modular system.

Curious? Then don’t hesitate to get in touch with us. Our experienced team will find the right solution for your specific requirements.

Industrial production is changing rapidly – due to expanded technical possibilities, a shortage of skilled workers and competitive pressure, automation is often the only way to remain successful on the market.

The efficient use of optical quality control systems is therefore becoming an important competitive advantage. Faster – more accurate – more efficient and ideally connected directly with the control of the production system – this is the infrastructure of optical quality control systems in the future.

In order to integrate such systems efficiently and economically into the production process, it makes sense to involve specialists as early as possible. The jumavis® team supports your planning of new production facilities with expertise in optical quality control – right from the start. This saves costs and increases integration quality and efficiency.

The jumavis® team knows the market, the current technical possibilities and, thanks to our close contact with developers and manufacturers, we occasionally take a look into the future. In our planning, we place particular emphasis on the integration of real-time monitoring systems. This allows us to identify potential quality problems at an early stage and make immediate adjustments to minimize rejects and maximize product quality. The solution developed can be integrated in advance into a virtual model of the production system (digital twin) to check their efficiency.

Where possible, we are already using innovative approaches such as artificial intelligence (AI) and machine learning to further increase the performance of optical quality control. Our solutions evolve with technological progress.

Curious? Then don’t hesitate to get in touch with us. Even if yours planning lies far in the future.

jumavis® relies on future-oriented technology to be at the forefront in the high-speed sector. It is with great pleasure that we announce our partnership with Optronis GmbH from Kehl, a renowned manufacturer of high-speed cameras.

The decision for Optronis GmbH is based on their excellent reputation and their leading position in high-speed camera technology. The new „CamPerform series“ offers groundbreaking performance that enables precise and detailed recordings of very fast movements.

The small housings of the „CamPerform series“ (C-Mount, F-Mount, M42-Mount etc.) are equipped with CoaXPress interface version 2.0 to transfer up to 12.5 Gbps image data per channel (max. 4 channels). The cameras offer resolutions from 1 to 65 megapixels with frame rates of up to 3518 fps.

The image data is transmitted via standardized interfaces such as CoaXPress or CameraLink. This allows image processing in real time, which is why Optronis cameras are used for industrial monitoring tasks with particularly high performance where the human eye reaches its limits.

jumavis® customers can look forward to a significant improvement in recording speed and image quality. With its robust design and user-friendly operation, the „CamPerform series“ is particularly suitable for demanding applications.

The partnership between jumavis® and Optronis GmbH underlines our ongoing commitment to providing our customers with first-class technology and innovative services.

For further information, please do not hesitate to contact us.

Since September, jumavis® is a strategic sales partner of the Danish manufacturer DeltaPix and expands the product portfolio as a qualified partner for quality assurance in the micro area.

DeltaPix has been doing pioneering work in digital microscopy for more than 20 years and has developed many innovative and mature products during this period. Digital microscopes from DeltaPix are used worldwide in many universities, research institutes as well as industrial companies.

The DeltaPix product portfolio includes single components (e.g. microscope cameras, digital microscopes as well as various accessories such as light sources, microscope stands, manual & motorized stages) up to complete systems including intuitive measurement software in 2D and 3D.

Due to their high flexibility, DeltaPix components can be used to optimize and upgrade existing systems in the micro range. Compared to other suppliers, this allows functional extensions of existing configurations and new purchases with a significant price advantage.

A special feature is the DPX M12000, a high-precision, fully automatic digital microscope that offers imaging quality and features never before seen in this price range. The DPX M12000 enables 3D topography, high depth of field, auto-stitching, automatic scanning and much more.

DeltaPix CEO Steen Oersted: „In jumavis we see exactly the right partner to design and distribute our products and solutions to meet the customers‘ requirements through their long experience in machine vision.“ „For us, the partnership with DeltaPix is an important expansion of our range of solutions,“ said jumavis Managing Director Johanna Unrath.

DeltaPix CEO Steen Oersted and jumavis®

Managing Director Johanna Unrath confirm their future cooperation with a handshake.

As an experienced distributor, jumavis® offers its customers the possibility to send their parts to be tested. We work out the corresponding solution and present this e.g. via an online live demonstration.

jumavis® is looking forward to your inquiry and supports you to find a suitable and economic solution exactly for your task.

Curious? Then read application examples of the DPX M12000.

For further information please do not hesitate to contact us.

The requirements, but also the performance and application possibilities of optical quality control systems are constantly growing up and jumavis® as an experienced distributor is in the avant garde.

As now, jumavis® takes in its sales program the new Kowa LM6HC-SW, a 1″ C-mount industrial lens with 6 mm focal length, optimized for SWIR (shortwave infrared) applications. Kowa – with over 70 years of experience in designing and building high performance lenses – has been a jumavis® supplier since the beginning and our team knows about their quality and strengths.

The Kowa LM6HC-SW, with its high transmission from 800 nm to 1900 nm and 6 mm focal length and the resulting particularly wide field of view, is especially suited for biological research, solar cell quality control and waste sorting equipment monitoring. The 6 mm now completes the lens series from 6 to 50 mm focal length.

As manufacturer-independent distributor, jumavis® has the know-how to integrate this high-performance lens with a suitable camera and matching software into almost any installation in order to optimize the performance (even of existing systems).

This is one of the special strengths of jumavis®.

For further information please do not hesitate to contact us.

jumavis® is now the European general distributor of the American high-power LED manufacturer SPECTRUM ILLUMINATION.

So jumavis® provides as of now its customers exclusively throughout Europe particularly high-intensity lighting for unusual product sizes, large working distances and large image fields in its product range.

Furthermore, our comprehensive range includes waterproof and food-safe illumination systems for demanding applications, such as in the food and pharmaceutical sectors.

Lighting systems with various designs and in sizes that significantly exceed „normal“ dimensions cover even unusual requirements. For example, dome lights with a diameter of 85 cm or modular line lights with a length of more than 4 meters are possible.

With its strong partner SPECTRUM ILLUMINATION, jumavis® can implement customer-specific solutions very quickly. And this also under extraordinary and highly specialized requirements.

Curious? Then don’t hesitate and read our comprehensive collection of case studies with application examples of SPECTRUM ILLUMINATION lighting systems for solving some extremely challenging tasks.