RICOH SC-20 – Inspection Camera

RICOH SC-20 – Inspection Camera

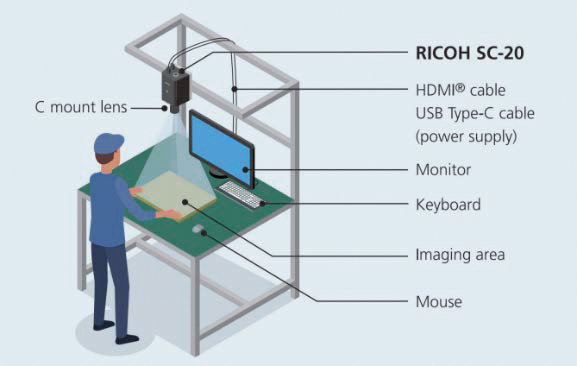

The RICOH SC-20 is an industrial inspection camera for quality control in assembly processes. It enables real-time inspection without the need for a PC. The RICOH SC-20 is capable of detecting errors such as missing parts or incorrect assembly positions.

Functions and applications for the RICOH SC-20

- Real-time quality control: The camera automatically checks the assembly structure of a component during the assembly process.

- Error detection: Detection of missing parts, incorrect components, or incorrect assembly sequence and output of an acoustic signal.

- PC-independent operation: The integrated PC enables easy installation and operation with a mouse, key-board, and monitor. Operation via a touch monitor is possible, and the camera can be integrated into a network.

- Optional functions: Barcodes, 2D codes, and OCR can be read. An external code reader or a screwdriver with torque detection can be connected.

Advantages of using the RICOH SC20

- Reduction of inspection errors: Digital inspection eliminates the variability of human quality control. The RICOH SC-20 emits an acoustic signal and shows the employee where an error has occurred.

- Easy implementation: Intuitive operation and PC independence facilitate introduction into the production process.

See here on YouTube how easily and professionally the RICOH SC-20 can optimize manual workstations and prevent errors.

Download data sheet